Trench shoring is a way to keep trench walls stable. It keeps workers safe when they work in or near trenches. This method helps lower the chance of accidents during digging. Without shoring, trenches might collapse and hurt or kill people. That’s why trench shoring is very important for safety on construction sites.

Why Trench Shoring is Important

Dangers of trench collapses in construction

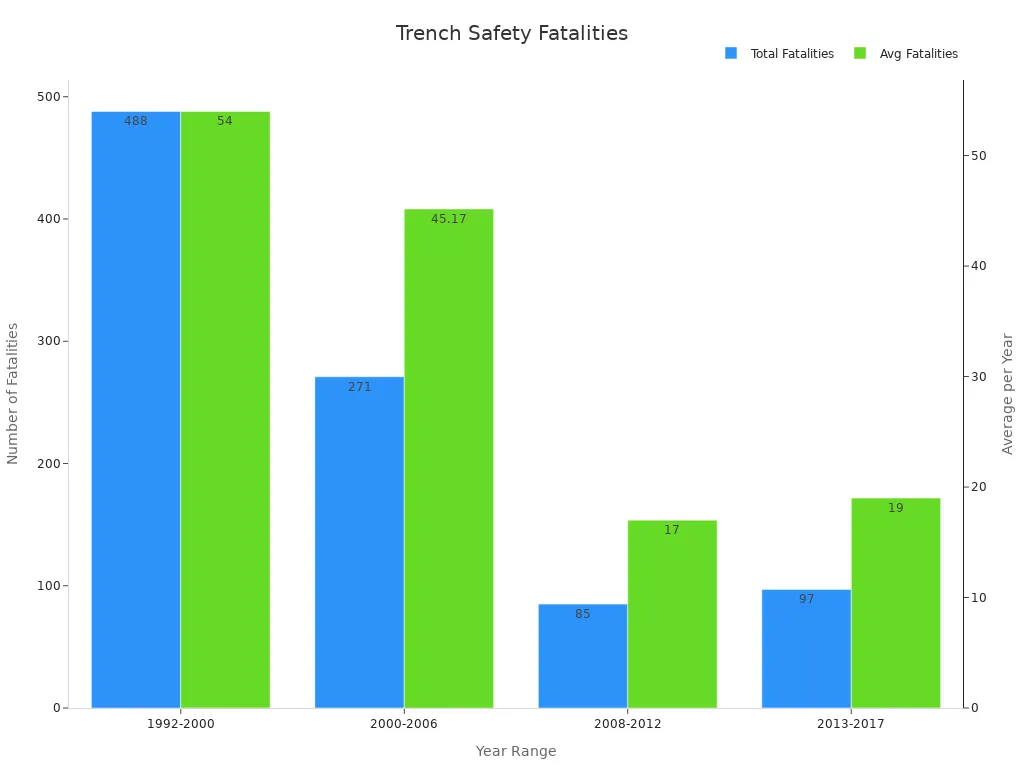

Trench collapses are very dangerous on construction sites. When a trench falls in, workers can get trapped under heavy dirt. This can cause serious injuries or even death. In 2022, 39 workers died from trench collapses, which was 60% more than in 2021. This shows why better safety rules are needed. Using trench shoring helps stop soil from falling in. It keeps trench walls steady and lowers the chance of accidents.

How trench shoring keeps workers safe

Trench shoring stops soil from falling into the trench. It protects workers by holding the walls in place. Unlike shielding, which only helps during a collapse, shoring keeps trenches stable all the time. Hydraulic shoring uses pressure to keep walls strong and safe. This also means workers spend less time in risky areas. If sloping or benching isn’t an option, trench shoring is the safest choice for digging.

Why trench shoring helps construction work

Trench shoring makes construction safer and faster. Hydraulic systems are light and easy to set up. Often, just one worker is needed to install them. This saves money and time. These systems can be quickly put in and taken out without workers going into the trench. By keeping trenches stable, shoring removes the need for extra supports. This saves time and materials, making it a key tool for today’s construction projects.

The FJD G31 Pro 3D Excavator Guidance System is the ultimate solution for trench shoring, ensuring safe and accurate excavation. With advanced GNSS and IMU technology, this system provides real-time 3D guidance, allowing operators to dig trenches with precise depth and slope while minimizing risks.

Whether you’re working on utility installations, foundation support, or large-scale infrastructure projects, the G31 Pro optimizes excavation for stable trench shoring, reducing rework and improving efficiency.

Types of Trench Shoring Systems

Hydraulic shoring systems

Hydraulic shoring systems are very effective for trench safety. They use hydraulic pressure to support trench walls and keep them stable. These systems are light, so one worker can set them up without entering the trench. This lowers the chance of accidents during installation. Hydraulic systems need a pressure of 1800 lbs and should be placed 18 inches from the trench edge. The distance between supports must be 4 feet, either vertically or horizontally.

Important features include gauges to spread pressure evenly and preloading to use the soil's natural strength. These systems are great for projects needing speed and safety. However, they might not work well in areas with underground pipes or cables, as these can block installation.

Aluminum and steel trench boxes

Trench boxes, also called trench shields, are another way to stay safe. Made from strong materials like aluminum or steel, they stop trench walls from collapsing. Aluminum boxes are light and easy to move, making them good for smaller jobs. Steel boxes are stronger and better for deeper trenches.

While trench boxes protect workers, they don’t stop falls. To improve safety, Temporary Edge Protection Systems (TEPS) can be used with them.

Timber shoring for smaller trenches

Timber shoring is an older method used for small trenches. It uses wooden supports to hold trench walls and protect underground pipes. But this method has some problems. Workers must go into the trench to set it up, which increases the risk of collapses. It also takes more time and effort compared to hydraulic systems. Timber shoring doesn’t work well in wet areas because water can weaken the wood.

Because of these issues, timber shoring is not the safest or fastest option. Modern systems like hydraulic shoring are better for safety and efficiency.

Selecting the right system for trench size and soil type

Picking the right trench shoring system depends on trench size, soil type, and project needs. For example, hydraulic shoring is good for smaller trenches with firm soil, while steel trench boxes are better for deep trenches. The table below shows key details for each system:

Trench Shoring System | Description | Key Requirements |

|---|---|---|

Hydraulic Shoring | Lightweight, uses hydraulic pressure | Needs specific pressure settings |

Aluminum Trench Boxes | Lightweight, easy to move | Best for smaller projects |

Steel Trench Boxes | Strong, good for deep trenches | Needs extra safety measures |

Timber Shoring | Traditional, takes more time | Best for small, dry trenches |

Always follow OSHA rules to stay safe. A trained person must check the system daily to make sure it works properly.

Safety Standards for Trench Shoring

OSHA rules for trench safety

The Occupational Safety and Health Administration (OSHA) has strict rules for trench work. These rules make sure employers follow safety steps to stop trench collapses. For example, OSHA 29 CFR 1926.651 tells employers to follow trench safety rules. OSHA 29 CFR 1926.652 explains what protective systems are needed based on trench depth.

In 2022, OSHA said 39 workers died in trench accidents. This was the highest number in 18 years. Because of this, OSHA made stricter rules and started teaching programs under the National Emphasis Program (NEP). These changes aim to lower accidents and save lives.

Regulation | What It Covers |

|---|---|

OSHA 29 CFR 1926.651 | Employers must follow trench safety rules. |

OSHA 29 CFR 1926.652 | Explains protective system needs for trench depth. |

NEP Update | Focuses on teaching and enforcing safety rules. |

Daily checks for shoring systems

Daily checks are needed to keep trench shoring systems safe. OSHA says a trained person must check trenches and systems every day. Checks are also needed after changes like heavy rain or shifting soil.

Important steps for checks include:

Looking for cracks or damage in shoring materials.

Making sure soil hasn’t weakened trench walls.

Checking that all supports are secure.

These checks help find problems early. This keeps workers safe and stops accidents.

Avoiding trench safety errors

Many trench accidents happen because of simple mistakes. Common errors include not using protective systems, ignoring weak soil, and skipping daily checks. Small companies with fewer than 50 workers cause 68% of trench deaths.

Company Size | Percent of Deaths |

|---|---|

<50 workers | 68% |

≤10 workers | 46% |

To avoid these mistakes, always follow OSHA rules. Use the right shoring system for the soil type. Do daily checks and train workers well. Following these steps can lower risks and save lives.

Image Source:

statics.mylandingpages.co

Image Source:

statics.mylandingpages.co

Trench shoring is key to keeping construction sites safe. Using the right systems stops collapses and keeps workers safe. Following OSHA rules helps make sure trenches stay secure. Daily checks and good training lower risks even more.

New ideas are improving trench safety. The table below shows some helpful advancements:

Innovation | Description | Benefits |

|---|---|---|

Flex Shield Material | Uses soil pressure to fit tightly in trench walls. | Improves safety in small spaces like manhole projects. |

Hydraulic Shoring | Uses hydraulic tools to hold trench walls steady. | Gives strong, safe support for deeper trenches. |

Pneumatic Shoring | Uses air pressure to keep trench walls stable. | Easy to set up and works in many trench types. |

Using these new tools makes trench work safer and faster. Always focus on safety to protect workers and finish projects successfully.

FAQ

What is the main purpose of trench shoring?

Trench shoring prevents trench collapses. It keeps workers safe by stabilizing trench walls and reducing the risk of dangerous situations during excavation.

How often should trench shoring systems be inspected?

You should inspect trench shoring systems daily. A trained professional must also check them after events like heavy rain or soil shifts.

Can trench shoring be used in all soil types?

Yes, but you must choose the right system. For example, hydraulic shoring works well in firm soils, while steel trench boxes suit deeper or unstable trenches.