The future of building is changing with new construction technology. These tools make work faster and help protect the planet. Building work is expected to grow 70% by 2040. Money made will go from $13 trillion in 2023 to $15.5 trillion by 2030. Tools like AI, IoT, and BIM are changing how we build through advanced construction technology. They help create smarter and greener ways to work.

FJD Machine Control Solutions – Advancing Construction Technology

FJDynamics is revolutionizing construction technology with cutting-edge machine control systems. Designed to enhance precision, efficiency, and safety, these solutions integrate GNSS and IMU technology to provide real-time guidance, automate operations, and reduce rework.

Whether excavating, grading, or dozing, these systems help construction professionals complete projects faster and more accurately while lowering operational costs.

Advanced Construction Technology Solutions:

FJD G31 Pro 3D Excavator Guidance System – Ensures centimeter-level accuracy for trenching, foundation digging, and earthmoving with real-time 3D guidance.

FJD H36 Pro 3D Motor Grader Control System – Delivers precise blade control, optimizing road grading, site leveling, and slope accuracy.

FJD H39 Pro 3D Dozer Control System – Automates dozer blade movements for efficient land clearing, grading, and construction site preparation.

By integrating these smart construction technologies, companies can increase productivity, improve accuracy, and enhance job site safety. Upgrade your construction operations with FJD’s machine control solutions. Get a quote today and build smarter!

Artificial Intelligence (AI) Changing Construction

How AI is Used in Construction

Predicting problems for better planning

AI helps plan construction projects smarter. It spots problems early, so you can fix them before they happen. This saves time and resources. A study says AI can boost construction work by 20%. This makes it a big help for planning projects.

AI tools for design and building

AI tools make designs easier and improve building steps. They pick the best materials, layouts, and methods for your project. Using AI saves time and cuts costs. These tools also give instant updates, keeping designs smart and useful.

Watching for risks in real-time

AI makes construction safer by spotting dangers quickly. It checks machines, workers, and the environment to stop accidents. Companies using AI safety tools have fewer accidents, up to 25% less. This keeps workers safe and lowers insurance costs.

Why AI is Good for Construction

Better decisions and fewer mistakes

AI helps make better choices by studying lots of data fast. It gives tips on materials, timelines, and budgets. This reduces errors and keeps projects running smoothly.

Avoiding delays and extra costs

AI tools help projects stay on time and on budget. They manage resources well and stop cost overruns. Real-time updates keep everything on track.

Safer work with smart insights

AI predicts risks and suggests ways to avoid them. It spots dangers early to protect workers and equipment. This leads to fewer accidents and safer job sites.

Problems with Using AI

High costs to start

Using AI needs a lot of money for tools and training. Small companies may find it hard to afford. This slows down how fast AI is used in construction.

Not enough trained workers

AI needs skilled people to run it. But over half of construction companies say they don’t have enough trained staff. Training programs are needed to fix this problem.

Keeping data safe

AI uses a lot of data, which can cause privacy worries. Protecting this data is important to avoid leaks. Strong security is needed to keep information safe.

Robotics and Automation in the Construction Industry

Robotics and automation are changing how construction is done. These tools make work faster, cheaper, and safer for everyone.

Uses of Robotics

Self-driving construction machines

Machines like self-driving bulldozers and diggers are now common. They work on their own, doing tasks like digging with accuracy. You can program them to follow steps, which avoids mistakes and speeds up work.

Robots for bricklaying and 3D printing

Robots now do jobs like laying bricks quickly and neatly. They can lay thousands of bricks in one day. 3D printers build parts of buildings layer by layer. This method uses fewer materials and creates less waste, saving money and helping the planet.

Drones for checking and surveying

Drones act like flying cameras. They scan large areas fast and take clear pictures. You can use them to check tall buildings or bridges safely. Drones also give live updates, helping you track progress easily.

Advantages of Robotics

Better speed and accuracy

Robots finish tasks faster and more precisely. They follow instructions exactly, making fewer mistakes and improving quality.

Lower labor costs and less strain

Robots take over hard jobs, saving money on workers. They also reduce injuries and tiredness by doing heavy tasks.

Quicker project completion

Robots don’t need breaks and can work all day. This helps finish projects sooner than planned.

Problems with Using Robotics

Expensive to start

Buying robots and training workers costs a lot. Small companies may struggle to afford this technology.

Hard to fit into current work

Adding robots to your work process can be tough. Workers need training to work well with these machines.

Safety and rule concerns

Using robots brings new safety and legal issues. You must follow rules and make sure workers stay safe.

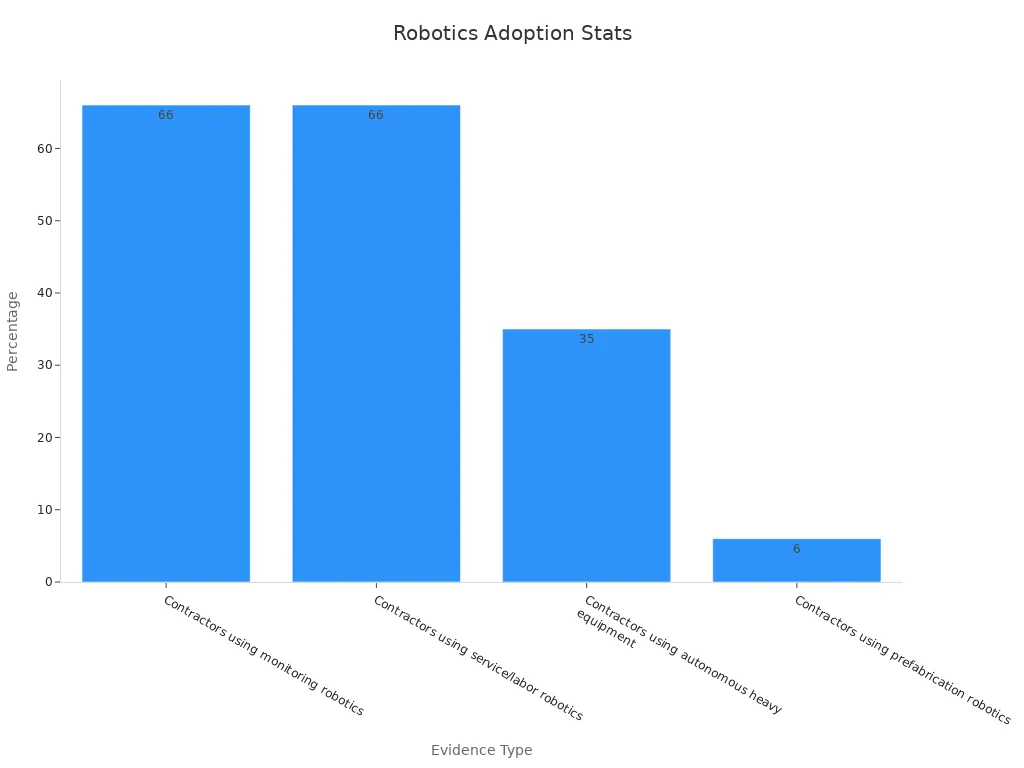

Studies show 66% of builders use service robots, and 35% use self-driving machines. But only 6% use robots for prefabrication. This shows robotics is growing, but some areas are slower to adopt.

Sustainable Construction Technologies for a Greener Future

How Sustainability Tech is Used

Eco-friendly materials and building methods

Builders now use materials like recycled steel, bamboo, and low-carbon concrete. These materials cut waste and are better for the planet. Prefabrication also helps by reducing waste and speeding up building.

Energy-saving building designs

Smart windows and solar panels save energy and lower bills. Adding insulation and natural airflow makes buildings even more energy-efficient.

Carbon-neutral building projects

Carbon-neutral projects balance emissions by using clean energy. Many companies follow these methods to meet stricter rules and build greener.

Why Sustainable Construction is Important

Less harm to the environment

Green building methods reduce pollution and save resources. Using renewable materials and energy-efficient designs helps protect the Earth.

Saves money over time

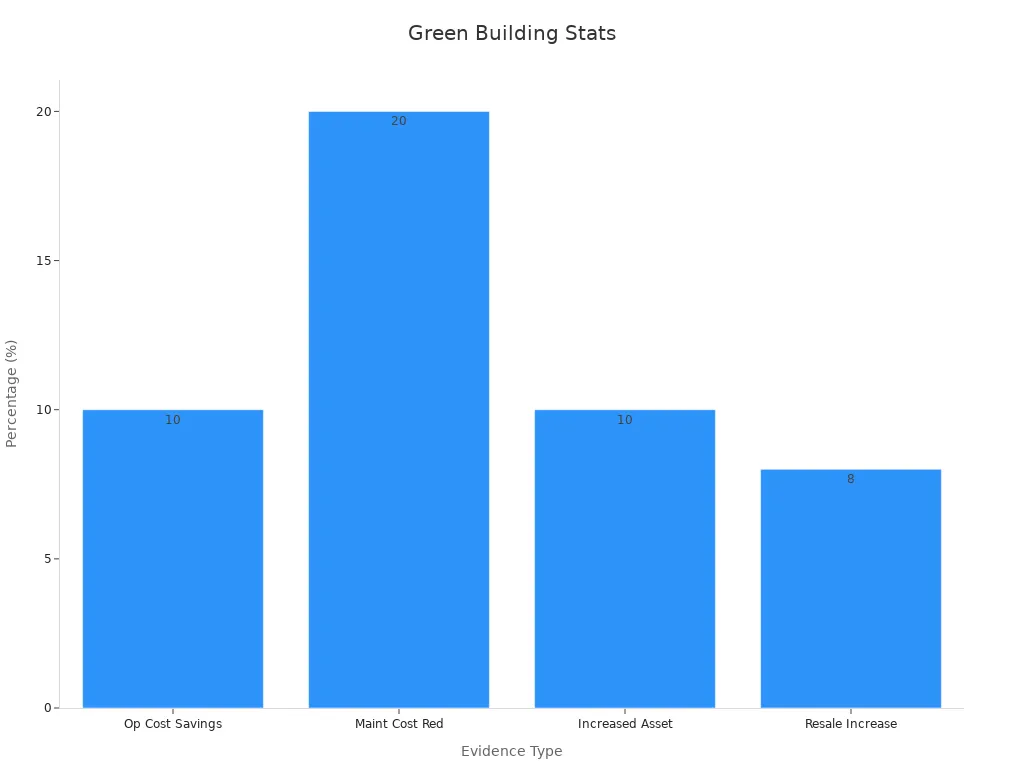

Green buildings cost less to run. Adding eco-friendly features can cut costs by 10% in one year. LEED-certified buildings also have 20% lower maintenance costs.

Better value and meeting rules

Sustainable buildings attract renters and increase property value. Renters pay more for green spaces than regular ones. Meeting green standards also keeps you within the law.

Problems with Going Green

High starting costs

Building green needs more money at first. Small companies may struggle because of these high costs.

Hard to find materials and experts

Green materials and skilled workers are not always easy to get. This slows down how fast companies can use green methods.

Sticking to old ways

Some companies don’t want to change their usual methods. This is the biggest challenge, showing the need for education and rewards.

The green construction market is growing fast. It could make $1,195.28 billion by 2033. This shows more people care about the planet and follow stricter rules. Sustainability is now a big focus in construction.

Digital Transformation Changing Construction Industry Trends

Digital tools are changing how construction works. They make tasks faster, teamwork better, and decisions smarter. These new technologies set higher standards for planning and building projects.

How Digital Tools Are Used

3D Models with BIM

BIM creates 3D models of buildings before they are built. It finds design problems early, saving time and cutting mistakes. BIM also helps teams work together better, lowering costs and improving results.

Cloud Tools for Managing Projects

Cloud tools store project data in one place for everyone to use. They replace paper files, saving money and making things clear. These tools give live updates, so everyone knows what’s happening.

Virtual Reality for Design Previews

Virtual reality shows designs before building starts. You can "walk" through the project to see how it will look. This helps teams and clients understand the plan and avoid confusion.

Why Digital Tools Help

Better Teamwork and Communication

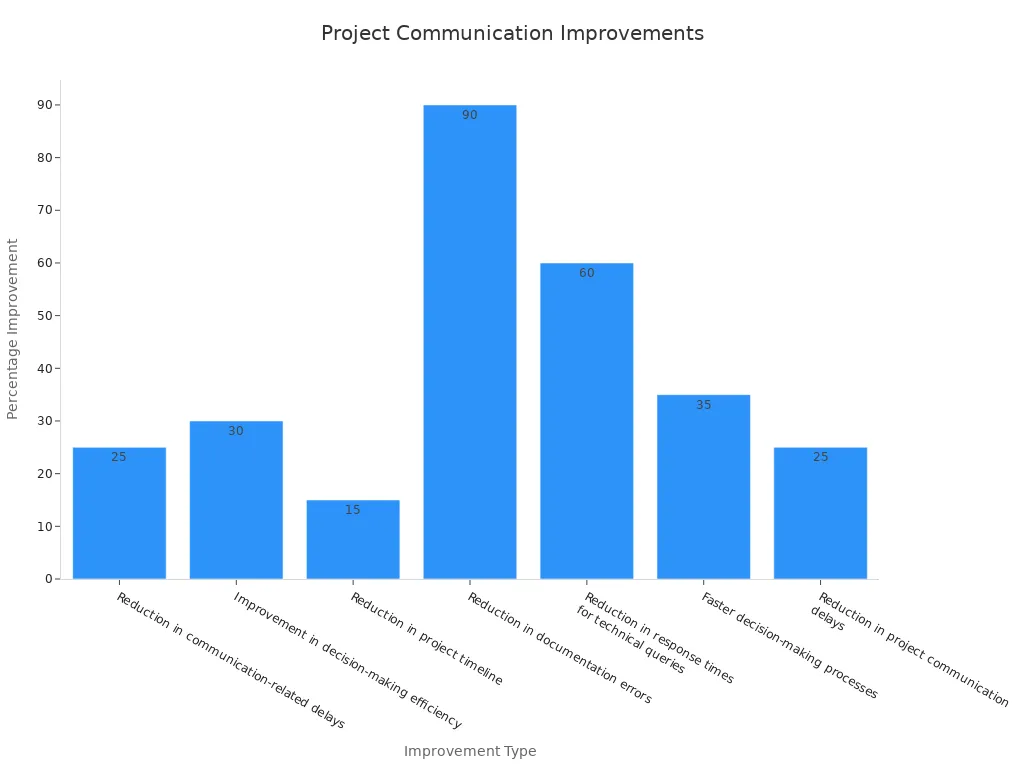

Digital tools improve teamwork with live updates and shared files. For example:

Live updates cut delays by 25%.

Mobile apps let workers log data offline.

Linking tools to systems keeps info flowing smoothly.

More Accurate Designs and Building

Digital tools fix version mix-ups, saving $280,000 in rework costs. They also speed up decisions by 35%, keeping projects on schedule.

Quick Data for Smart Choices

Live data shows how projects are doing right away. Dashboards track progress, helping managers act fast and avoid delays.

Problems with Digital Tools

Hard to Train Workers

Learning new tools takes time and training. Many companies struggle to teach their workers, slowing down progress.

Keeping Data Safe

Digital tools use lots of data, so security is key. Protecting this data from hackers is very important.

Needing Good Internet

Cloud tools need strong internet to work well. Bad connections can slow work, especially in faraway places.

A project at Madison Square Tower shows how digital tools help. Using one platform, they cut RFI response times by 42%, saved $280,000 in rework, and made decisions 35% faster.

Digital tools are not just cool; they are needed to stay ahead. By using them, you can meet client needs, work smarter, and build greener projects.

Advanced Materials and Building Methods

How Advanced Materials Are Used

Concrete that fixes itself

Self-healing concrete is a big change for building. It uses bacteria or chemicals to fix cracks on its own. This lowers repair costs and makes buildings last longer. It’s great for projects like bridges and tunnels that need to stay strong for years.

Strong but light materials

Materials like carbon fiber and fiberglass are strong but not heavy. They work well for tall buildings and modular projects. These materials also save energy by making structures lighter, which helps with transport and setup.

Building with pre-made parts

Prefabrication and modular building are changing construction. Parts are made in factories and then put together on-site. This speeds up building and reduces waste. Modular designs can also change easily to fit new needs, matching today’s tech trends.

Why Advanced Materials Are Helpful

Longer-lasting buildings

Materials like self-healing concrete and composites make buildings stronger. They handle wear and tear better, so repairs are needed less often. This saves time and money over the years.

Faster building with less waste

Using prefabrication and 3D printing makes building quicker. These methods create exact parts, cutting down on wasted materials. Projects finish faster while keeping high quality.

Flexible designs for different needs

Modular building and digital tools make it easy to customize. Advanced materials allow creative solutions for all kinds of projects. From homes to offices, these materials meet many needs.

Problems with Advanced Materials

Hard to use everywhere

It’s tough to make enough advanced materials for everyone. Cities are growing fast, but production can’t always keep up. This slows down how widely they’re used.

High starting prices

Advanced materials cost more than regular ones at first. Many companies don’t want to spend extra money. But new ideas aim to lower costs and show long-term savings.

Need for trained workers

Special skills are needed to use advanced materials. Finding trained workers can be hard. Training programs can help teach people and speed up the use of these materials.

The market for advanced building materials was worth $50 billion in 2023. By 2032, it could grow to $95 billion. Cities and eco-friendly ideas are driving this growth. Materials like strong concrete and composites are now key for better, longer-lasting buildings.

New construction technologies are changing how we build in 2025. Tools like AR, drones, and IoT make work faster and better. The table below shows how they help:

Technology Trend | How It Helps Construction |

|---|---|

Augmented Reality (AR) | Makes planning easier and teamwork better, improving accuracy. |

Building Information Modeling (BIM) | Creates digital models to help make smarter choices during projects. |

Drones | Speeds up site checks and reduces delays by surveying quickly. |

Generative AI | Improves designs and plans, saving money and time. |

IoT and Advanced Analytics | Collects live data to boost productivity and make work more reliable. |

Using these tools helps construction grow and succeed. You can measure progress with things like safety, speed, and quality.

Metric | Why It Matters |

|---|---|

Costs | Keeps track of spending and budget. |

Schedule Adherence | Makes sure projects finish on time. |

Quality | Ensures buildings are made well. |

Safety | Protects workers and lowers accidents. |

Environmental Effects | Checks how building affects the planet. |

It’s time to use these new ideas. By trying them now, you can lead the way to smarter and greener building. Start today to create a better future!

FAQ

What is the most important construction technology trend in 2025?

All trends are important, but AI and robotics stand out. AI helps with planning and safety. Robotics makes tasks like bricklaying faster. Together, they change how buildings are made.

How can small companies afford these technologies?

Start with cheaper tools like drones or cloud software. Add advanced tools later as your budget allows. Many tools grow with your needs, so you can start small.

Are these technologies difficult to learn?

Some tools need training, but many are easy to use. Tools like BIM and cloud platforms often have guides. Online courses can also help your team learn quickly.

Do these technologies harm the environment?

No, they often help the planet. Green materials, energy-saving designs, and methods like 3D printing reduce waste. These tools let you build smarter and protect nature.

How do I ensure data security when using digital tools?

Use strong passwords and encryption to keep data safe. Pick tools with good security features and update them often. Teach your team safe online habits to avoid risks.