Managing construction equipment management means planning, caring for, and tracking machines. It helps machines work well and avoids delays. Good construction equipment management saves money and keeps projects on time. Taking care of equipment also makes the site safer and follows rules.

Using smart strategies in construction equipment management can make machines last longer and cost less. This helps work run smoothly and reach project goals easily.

Revolutionize Construction Equipment Management with FJDynamics Solutions

Effective construction equipment management demands precision, efficiency, and real-time control—and that’s exactly what FJDynamics delivers. The G31 Pro 3D Excavator Guidance System, H36 Pro 3D Motor Grader Control System, and H39 Pro 3D Dozer Control System bring intelligent automation to your heavy machinery fleet. These systems provide real-time data, precise machine control, and seamless integration with digital project management platforms—ensuring your equipment operates at maximum productivity with minimal downtime. Perfect for contractors and project managers aiming to streamline operations and reduce costs.

Take control of your fleet—Request a quote today and optimize your construction equipment management strategy!

Understanding Construction Equipment Management

Definition and Purpose

Construction equipment management means planning, caring for, and tracking tools. It helps machines work well and keeps costs low. Managing equipment properly ensures tools are ready when needed. This reduces delays and improves project results.

The table below shows the main goals of construction equipment management:

Purpose of Construction Equipment Management | Description |

|---|---|

Project Efficiency | Keeps tools in good shape to boost work speed and profits. |

Maintenance and Scheduling | Makes sure tools are fixed and in the right place on time. |

Profitability of Investments | Helps tools stay useful and valuable as project needs change. |

Knowing these goals helps you match your equipment plans with project needs.

Key Objectives of Effective Equipment Management

Good equipment management aims to meet clear goals. These goals help track how well your equipment program works. The table below lists the main goals:

Key Performance Objective | Description |

|---|---|

Track and Justify Financial Benefits | Shows money saved by using condition-checking tools to others. |

Identify and Address Bad Actors | Finds poorly working tools and fixes problems quickly. |

Eliminate Inefficiencies | Spots and removes waste in equipment use and care. |

Focusing on these goals helps improve your tools and project success.

Common Challenges in Equipment Management

Managing construction tools can be tricky. Problems can slow down work and cause delays. Below are some common issues companies face:

Tracking machines and equipment: Watching over tools in many places is hard.

Enabling remote management: Checking tool health from far away can be tough.

Pinning down utilization: Knowing how much tools are used at each site is tricky.

Allocating and charging costs: Tracking all tool costs takes a lot of time.

Closing books at the end of the project: Recording tool data for money reports is often hard.

Fixing these problems is key to managing tools well. Using smart plans can help tools work their best.

Importance of Construction Equipment Management

Improving Project Efficiency and Deadlines

Good construction equipment management helps projects run smoothly and on time. Keeping machines in good shape avoids delays and downtime. Watching how tools are used helps find problems and fix them fast.

Important numbers to track for better efficiency:

Labor Productivity Rates: Shows how well workers use tools to finish tasks.

Equipment Utilization Rates: Tracks how often tools are used and how well.

Material Usage Efficiency: Checks if materials are used wisely to avoid waste.

Overall Equipment Effectiveness (OEE): Measures tool performance, availability, and quality.

Tip: Check these numbers often to keep your tools working well for your project.

Saving Money with Good Management

Taking care of tools the right way saves money. Fixing tools early costs less than waiting for big repairs. Quick fixes also stop long delays, saving time and cash.

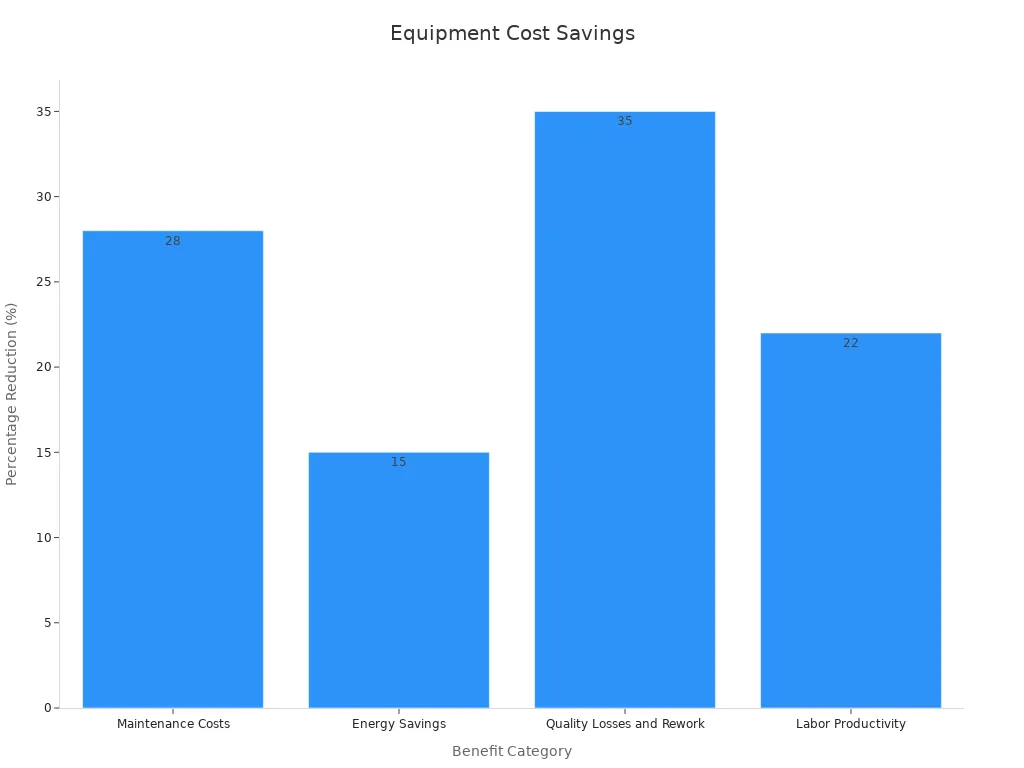

Studies show these savings from good tool care:

Benefit | Percentage Saved |

|---|---|

Maintenance Costs | |

Energy Savings | 15% |

Quality Losses and Rework | 35% |

Labor Productivity | 22% |

Managing tools well helps you spend money wisely and save more over time.

Keeping Workers Safe and Following Rules

Safety is very important when using construction tools. Checking tools makes sure they work safely and don’t break down. This lowers the chance of accidents and keeps work going.

Key safety steps include:

Checking tools to make sure they work safely.

Following rules to keep workers safe and meet standards.

Planning ahead to stop accidents and tool problems.

Risks of Poor Construction Equipment Management

Downtime and Project Delays

Bad equipment management causes delays and downtime. If tools aren’t cared for, they can break suddenly. For example, skipping oil changes can make machines stop working. This slows projects and adds costs like repair work, renting tools, and late fees. These problems hurt profits and damage your company’s image.

Downtime is very expensive. One hour of downtime costs $260,000 on average. Old machines, which cause 44% of surprise breakdowns, make delays worse. Doing regular maintenance can lower these risks and keep projects moving.

Increased Maintenance Costs

Not taking care of tools raises repair costs a lot. Ignoring small fixes can lead to big, expensive problems. For instance, skipping a small repair can break major parts. Studies show delayed fixes cost 10 times more than regular care.

Breakdowns also cost more money. Tool failures cause 42% of the $50 billion lost yearly from downtime. Poor care lowers production by 20%, leading to overtime, part replacements, and emergency repairs. A good maintenance plan can save you from these extra costs.

Reduced Equipment Lifespan

Bad tool care makes machines wear out faster. Regular maintenance keeps tools working longer. Without it, they break more often and need replacing sooner. This raises costs and slows work.

Old tools break more easily. Small problems grow into big ones if ignored, making tools useless. Managing your tools well helps them last longer, break less, and save money in the long run.

Safety and Liability Concerns

Safety is very important in construction equipment management. Broken tools can cause accidents or hurt workers. If machines fail, they might damage property or harm people. Keeping your team safe helps avoid big problems and costs.

Checking tools often is key to safety. Regular inspections find problems before they cause harm. For example, worn brakes or loose parts can lead to injuries. Fixing these issues quickly keeps the worksite safe.

Teaching workers how to use tools is also important. Trained workers make fewer mistakes that could cause injuries. Give clear instructions and hands-on practice for every machine. This improves safety and helps work get done faster.

Following safety rules is a must. Construction sites need to meet industry standards to avoid fines. Sticking to these rules shows you care about safety and lowers risks. For example, meeting OSHA standards helps prevent legal trouble.

To stop injuries, create a strong safety plan. Include regular tool checks, worker training, and rule-following in your plan. These steps make the site safer and protect your business from problems.

Actionable Tips for Effective Equipment Management

Set Up a Preventive Maintenance Plan

A preventive maintenance plan keeps your tools in great shape. It schedules fixes before problems happen, so machines stay reliable. Regular care stops sudden breakdowns that cause delays and cost money.

Studies show proactive care is very helpful. For example, using tools to estimate repair costs can guide fixes like remanufacturing or refurbishing. These methods save money and help the environment. By using these strategies, you can make your tools last longer.

To start a good maintenance plan, follow these steps:

Make a daily construction equipment maintenance checklist for key tasks.

Plan regular checks and repairs ahead of time.

Use a construction equipment management checklist to track completed work.

Monitor Equipment Use and Performance

Watching how tools are used helps you find problems early. It also shows where you can save time and money. By studying this data, you can improve how work gets done and meet your goals.

Tracking performance brings clear benefits:

Better processes make work smoother.

Regular reviews solve problems faster.

Numbers like productivity rates show how well tools are used.

Companies that track progress often reach their goals faster. Key numbers like equipment usage and worker productivity give useful insights.

Teach Workers How to Use Tools Safely

Training workers on tool use is very important. It helps them work faster and make fewer mistakes. Training also lowers the chance of accidents, keeping everyone safe.

Reports show training has many benefits:

Benefit | Description |

|---|---|

Faster work | Workers finish tasks quicker with proper training. |

Fewer mistakes | Training helps workers do things right the first time. |

Better efficiency | Skilled workers make work smoother and save resources. |

Happier workers | Safety training builds trust and confidence. |

Lower costs | Training reduces insurance and legal expenses. |

To train your team well, set clear rules for tool use. Offer hands-on practice and regular updates on safety. This improves work quality and creates a safer workplace.

Implement a Centralized Equipment Management System

A centralized system helps you manage tools and machines better. It combines all equipment data into one place. This makes decisions easier, reduces waste, and improves project results.

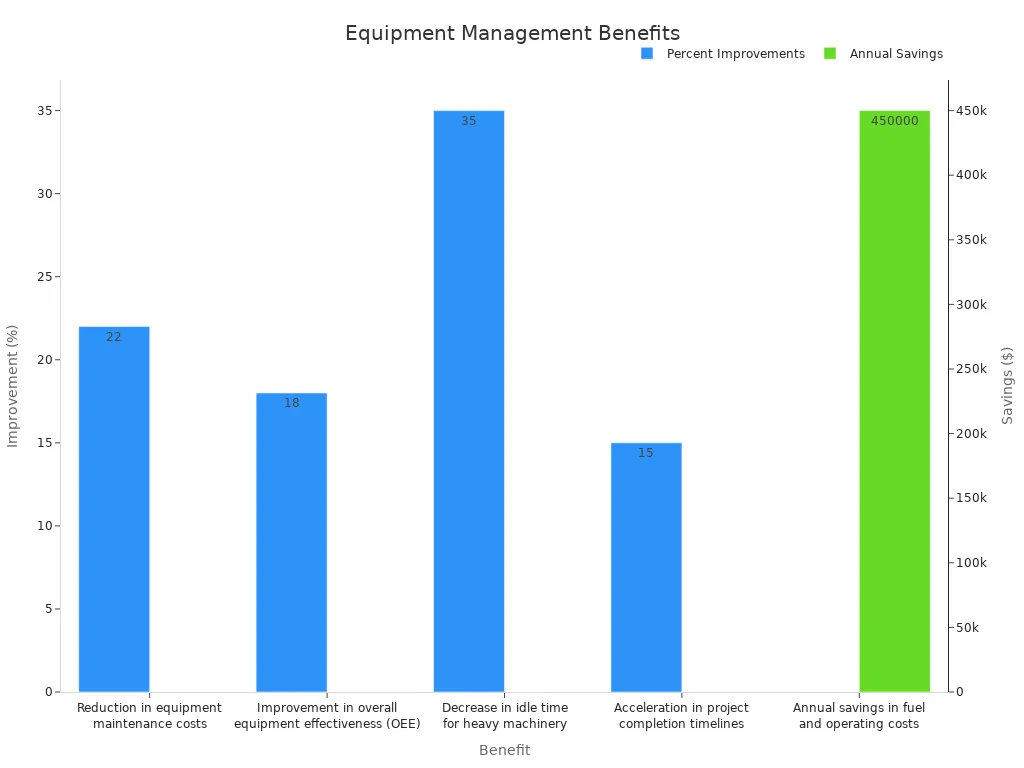

Benefits of a Centralized System

Using this system has clear advantages. Construction companies have saved money and worked more efficiently. Below are some key benefits:

Benefit | Improvement Percentage/Amount |

|---|---|

Lower maintenance costs | |

Better overall equipment effectiveness (OEE) | 18% |

Less idle time for heavy machines | 35% |

Yearly savings on fuel and operating costs | $450,000 |

Faster project completion | 15% |

Key Features to Look For

Choose a system with features that make work easier. Look for:

Real-time tracking: See where tools are and how they’re used.

Maintenance scheduling: Get automatic reminders for repairs.

Data analytics: Learn how tools perform and cost.

Integration capabilities: Connect with your current software easily.

Using this system keeps tools in great shape, reduces downtime, and speeds up projects.

Leveraging Technology for Construction Equipment Management

Benefits of Equipment Management Software

Using construction equipment management software makes handling tools easier. It saves time, cuts costs, and simplifies tasks. This software helps you track, maintain, and improve your equipment in one place.

Here are the main benefits of this software:

Benefit | Description |

|---|---|

Helps use tools better, increasing work speed. | |

Complete Visibility of Assets | Tracks tools live, saving time finding lost items. |

Automating Regular Maintenance | Sends reminders for fixes, stopping expensive breakdowns. |

Avoiding Equipment Theft & Loss | Lowers theft and loss, saving money daily. |

Eliminating Ghost Assets | Tracks tools correctly, avoiding fines for missing items. |

Reporting & Statistics | Creates reports to check performance and plan better. |

This software gives real-time updates on your tools, improving control. It also automates tasks like scheduling repairs, saving time for other jobs.

Role of IoT in Equipment Tracking

The Internet of Things (IoT) has changed how tools are tracked. IoT devices like sensors and GPS trackers give live updates on tool location and condition. This makes managing tools more accurate and efficient.

Here’s how IoT helps track tools better:

Evidence Type | Description |

|---|---|

Shows live info about tools, making management easier. | |

Early Fault Detection | Spots problems early, allowing quick fixes. |

Reduced Downtime | Stops surprise failures, keeping work on track. |

Optimized Utilization | Tracks tool use to share resources wisely. |

IoT devices prevent delays from lost or broken tools. For example, sensors can find wear early, so you fix it before it worsens. This reduces downtime and keeps projects moving.

Predictive Maintenance with Data Analytics

Predictive maintenance uses data to stop tool failures before they happen. By studying past and live data, you can find signs of problems early. This method fixes tools based on need, not a set schedule.

Benefits of predictive maintenance include:

Cost Savings: Stops surprise repairs, saving money and time.

Increased Equipment Lifespan: Fixes issues early, helping tools last longer.

Enhanced Productivity: Reduces delays, keeping projects on time.

Data-Driven Decision Making: Gives insights for smarter planning.

Key parts of predictive maintenance are:

Historical Data: Looks at past records to find problem patterns.

Real-Time Monitoring: Uses sensors to watch tool performance.

Sensor Data: Collects info to predict future issues.

Advanced tools like machine learning study big data to predict failures accurately. Predictive maintenance lowers costs, boosts efficiency, and keeps tools reliable.

Mobile Tools for On-Site Equipment Tracking

Mobile tools have changed how we track construction equipment. These apps let you check equipment location, use, and performance instantly. With mobile devices, you can decide faster, avoid delays, and keep projects running smoothly.

Benefits of Using Mobile Tools

Mobile tools bring many benefits to managing equipment. Here’s how they help:

Less time on paperwork: Digital records replace manual logs.

Faster task completion: Quick access to data helps finish jobs on time.

Better technician work: Apps help fix problems quickly and easily.

Happier clients: Good equipment care leads to better results.

These tools make work easier and save time.

Mobile Tools Performance Results

Studies show mobile tools improve equipment tracking. The table below shows key results:

Metric | Result |

|---|---|

Paperwork time saved | |

Task completion rates | 20% higher |

Client satisfaction | Better |

These numbers prove mobile tools make a big difference.

Features to Look for in Mobile Tools

Pick mobile tools with features that make work simple. Look for:

Live updates: See equipment status and location instantly.

Easy to use: Choose apps that are simple to navigate.

System connection: Link the app to your current tools.

Offline use: Work even without internet access.

How Mobile Tools Help on Site

Mobile tools improve tracking in many ways. GPS shows where equipment is at all times. Alerts remind you about repairs to avoid breakdowns. Technicians can report issues directly from the field using apps, speeding up fixes.

Using mobile tools makes managing equipment easier, reduces delays, and improves project success.

Choosing and Replacing Construction Equipment

Picking the Right Equipment

Choosing the right tools helps your project run smoothly. Start by thinking about what your project needs. Look at the tasks, site conditions, and project size. Make sure the equipment fits the space and can handle the work.

Using multi-purpose machines, like backhoe loaders, saves time and money. These tools can do many jobs, so you need fewer machines.

Here are some important things to think about when picking equipment:

Criteria | What It Means |

|---|---|

Equipment Usefulness | The tool should match the project’s needs. |

Suitability | It must be right for the job you’re doing. |

Durability | Strong tools last longer and work better. |

Cost-Effectiveness | Think about buying, running, and fuel costs. |

Maintenance Ease | Easy-to-fix tools save money over time. |

Safety | The tool must keep workers safe and meet safety rules. |

Good material handling is also key. Tools like forklifts or conveyor belts help move and store materials quickly, making work faster.

Knowing When to Replace Equipment

Replacing old tools at the right time saves money and avoids delays. Watch for signs like frequent breakdowns, higher repair costs, or poor performance. If fixing a tool costs more than half its value, it’s time to replace it.

Think about selling old tools for cash. Machines with good resale value can help pay for new ones. Also, older tools might not meet safety rules or project needs, so replacing them is important.

Check how tools are working regularly. Keep track of downtime and repair needs to decide if you should fix, replace, or retire them.

Balancing Costs and Long-Term Value

It’s important to balance upfront costs with long-term savings. Cheaper tools might cost less now but could need more repairs later. Spending more on strong, efficient tools saves money over time.

For example, Siemens found that using modern systems cut costs by 30%. These systems used automation and real-time data to reduce downtime and improve work. Similarly, buying high-quality tools means fewer breakdowns and longer use.

When looking at costs, think about buying price, fuel use, and savings from less downtime. A careful cost check helps you pick the best tools for your project.

Leasing vs. Buying: Choosing the Best Option

Deciding to lease or buy construction equipment depends on your needs. Each choice has its own benefits and downsides. Knowing these differences helps you pick the right option.

Advantages and Disadvantages of Leasing Equipment

Leasing is flexible and costs less upfront. It lets you use new tools without owning them. But leasing isn’t always the best choice. The table below shows the main pros and cons:

Pros of Leasing | Cons of Leasing |

|---|---|

No ownership or resale value later | |

More flexibility for projects | Lease terms might last too long |

Tax deductions over time | May have higher interest rates |

Leasing is great for short-term projects or avoiding big upfront costs. It also offers tax savings since lease payments can be deducted.

Why Buying Equipment Can Be Better

Buying gives you full ownership and long-term value. You can use the tools anytime without worrying about lease rules. Owning equipment builds equity, which helps if you sell it later. However, buying costs more upfront and needs regular maintenance.

Things to Think About Before Deciding

To choose between leasing or buying, look at your budget and needs. Leasing lowers monthly costs, while buying gives ownership and saves money long-term. Taxes matter too. Leasing allows deductions over time, while buying offers depreciation benefits.

Compare the total costs of both options. Think about how often you’ll use the tools and whether flexibility or ownership is more important. Match your choice to your project goals for the best results.

By thinking about these points, you can pick the best option for your projects and budget.

FAQ

1. What is the main goal of construction equipment management?

The main goal is to keep tools working well, safely, and affordably. Good management lowers downtime, makes tools last longer, and keeps projects on track.

2. How can you track equipment usage effectively?

You can use special software or smart devices like IoT tools. These give live updates about where tools are and how they’re working.

3. Why is preventive maintenance important?

Preventive maintenance stops big repairs and surprise breakdowns. It keeps tools safe and ready to use.

4. Should you lease or buy construction equipment?

It depends on what your project needs. Leasing is good for short jobs, while buying is better for long-term use.

5. How does technology improve equipment management?

Technology makes tracking and fixing tools easier. Tools like IoT, apps, and smart systems help manage equipment better.