The construction industry is changing quickly in 2025, influenced by emerging construction industry trends. Green building ideas are creating new ways to build, while technology is transforming how projects are planned and executed. From eco-friendly methods to digital tools, the trends of 2025-2030 emphasize efficiency and creativity. By learning these trends, you can confidently navigate the future of building.

FJD Technology Leading the Future of Construction Industry Trends

As the construction industry rapidly evolves, smart automation, digital mapping, and real-time data are shaping the future of how we build. FJDynamics is at the forefront of this transformation, delivering advanced solutions that align perfectly with today’s top construction trends: automation, precision, and sustainability.

FJD G31 Pro 3D Excavator Guidance System – Part of the automation wave, this system enhances productivity on excavation sites with real-time 3D guidance and centimeter-level accuracy—reducing reliance on manual labor and increasing project speed.

FJD Trion V10i Mobile LiDAR Mapping System – Reflecting the rise of digital twin technology and smart planning, this mobile mapping solution delivers fast, accurate terrain and infrastructure scans for better decision-making.

FJD Trion S1 3D LiDAR Scanner – Supporting the push for as-built verification and construction digitization, the Trion S1 provides portable, high-resolution 3D scanning that fits perfectly into BIM workflows and QA/QC processes.

Together, these tools represent the future of construction—smarter, faster, and more connected.

Stay ahead of the trends—get a quote and bring cutting-edge FJD technology to your next project.

Sustainability Trends in the Construction Industry

Green Building Techniques

Green building methods are changing how we build today. They aim to protect the environment and use fewer resources. These methods save energy, water, and reduce waste. For instance, following green rules like LEED or ASHRAE 189.1 can cut environmental harm by 15-25%. These rules also help lower carbon emissions, energy use, and trash.

More builders are using green technology now. A Dodge survey found that almost half of builders expect most projects to be green by 2024. This shows how important eco-friendly building is becoming. By using these methods, you can help the planet and stay ahead in the industry.

Zero-Energy and Net-Zero Buildings

Zero-energy and net-zero buildings are leading the way in green construction. These buildings make as much energy as they use, often with solar power. New technology and government help are making these buildings more common. Projects like SPARCS show how cities are solving problems to build net-zero areas.

Fixing old buildings to save energy is also important. These changes lower energy bills and fight climate change. In 2025, building trends focus on energy-saving designs for a greener future.

Decarbonization and Carbon-Neutral Materials

Cutting carbon is a big goal in green building. Using materials like recycled steel and carbon-free concrete helps reduce pollution. These materials match the goals of eco-friendly construction.

Builders are also reusing materials to create less waste. This idea, called the circular economy, saves money and helps the planet. By using these ideas, you can join global efforts to fight climate change and meet green building needs.

Circular Economy in Construction

The circular economy is changing how construction is done. Instead of throwing things away, it focuses on reusing and recycling. This method helps save money and protects the environment.

Construction creates 38% of the world’s waste and uses 50% of resources. These facts show why change is needed. Using old materials like recycled steel or wood reduces waste. It also lowers costs and cuts pollution.

The circular economy helps more than just the planet. It creates jobs and saves money for businesses. By 2030, it could save $700 billion every year. This makes it an important trend in construction.

Here’s how the circular economy can help:

What It Does | How Much |

|---|---|

Saves money yearly | |

Creates jobs | Millions of new jobs |

Waste from construction | 38% of global waste |

Carbon emissions from construction | 40% globally |

Resources used by construction | 50% of the world’s total |

By 2025, using the circular economy will meet green goals. It’s about rethinking how to use materials to help the planet.

Technological Advancements Driving Construction Trends

Artificial Intelligence and Machine Learning

AI and ML are changing how construction works. They help by studying lots of data to make better choices. For example, ML can find risks, improve safety, and boost work speed. Construction projects create tons of data like emails and plans. But most of this data, about 95.5%, is not used. AI and ML can use this data to make work faster and easier.

AI also helps keep workers safe. It uses tools like cameras to spot dangers on sites. This helps stop accidents and keeps workers protected. AI also makes cost planning and resource use more accurate. This saves both time and money.

Robotics and Automation in Construction

Robots and machines are bringing new ideas to construction. They take over boring and repeated tasks. For example, robots can build walls, pour concrete, and put parts together. This lowers labor costs, which are 25-30% of total costs.

A study says 41% of companies think robots and AI help workers do more. Also, 35% of companies already use AI machines to work better. Using robots lets you finish jobs faster and with better quality. This saves time and gives great results.

3D Printing for Building Components

3D printing is changing how buildings are made. It builds parts layer by layer, cutting waste and saving materials. For example, 3D printing can make building 60% faster than old ways. It also cuts labor costs by up to 80% by needing fewer workers.

3D printing also helps with housing problems. Homes made this way can be built 20 times faster than normal homes. This makes it a great way to meet the need for cheaper homes. By using 3D printing, you can follow new trends and help create a greener future.

Digital Transformation and BIM (Building Information Modeling)

Digital tools are changing how construction projects are done. One key tool is Building Information Modeling (BIM). BIM creates detailed digital plans for projects. These plans help teams work together and avoid mistakes. You can see the whole project before building starts. This saves time and reduces errors.

BIM makes teamwork better by sharing data instantly. Everyone stays informed, which prevents confusion. Architects, engineers, and builders can spot problems early and fix them fast. This keeps projects on track and avoids extra work.

Here’s how BIM and digital tools improve projects:

Improvement Area | What It Does |

|---|---|

Speeds up work with better planning. | |

Lower Costs | Cuts waste and uses resources wisely. |

Better Teamwork | Helps teams share information easily. |

Organized Data | Keeps project details clear for smart decisions. |

Accurate Plans | Makes fewer mistakes and improves results. |

Using BIM and digital tools helps you follow new trends. It also prepares you for the future of construction.

Construction Management Software and Cloud Solutions

Software and cloud tools are changing how projects are managed. These tools track progress, manage resources, and check quality. Cloud systems let you access project info from anywhere. This makes teamwork easier and keeps tasks organized.

One big benefit is saving time. Smart scheduling tools find delays and help fix them. This keeps projects moving and avoids downtime. Automated systems also check safety and quality. This reduces risks and ensures good results.

Here’s how these tools improve project management:

Improvement Area | What It Does | Tools Used |

|---|---|---|

Spots delays and keeps projects on schedule. | Cloud software, smart scheduling tools. | |

Safety and Quality | Checks for problems and meets safety rules. | Automated systems, real-time monitoring tools. |

Productivity | Measures how well workers and machines are performing. | Dashboards, tracking systems. |

Risk Control | Finds risks and improves customer satisfaction. | Risk tools, feedback platforms. |

Customer Feedback | Uses reviews to make projects better. | Feedback tools, performance trackers. |

Workforce Development in the Construction Industry

Addressing Labor Shortages

The construction industry faces a big problem with not enough workers. Many workers, about 1 in 5, are over 55 years old. This means lots of them will retire soon. To keep up, the industry needs over 500,000 new workers. But almost 90% of companies say it’s hard to find people for jobs. These worker shortages cause delays, higher costs, and unhappy clients.

To fix this, companies should make jobs more attractive. Paying good wages and offering benefits can bring in skilled workers. Training programs can also help new workers learn faster. Solving this problem keeps projects on time and clients happy.

Statistic/Observation | Description |

|---|---|

Aging Workforce | 1 in 5 workers is 55 or older. |

Demand for New Workers | 500,000 new workers are needed. |

Difficulty Filling Positions | 90% of companies struggle to hire workers. |

Project Delays | Worker shortages cause delays and cost increases. |

Training Simulators and Virtual Reality for Skill Development

Training simulators and virtual reality (VR) are changing how workers learn. These tools let workers practice safely and avoid accidents. VR training helps workers remember lessons better, up to 75% more than old methods. It also makes learning faster and easier.

For example, companies using VR for safety training see fewer accidents. Workers feel more confident after practicing in a safe space. Using VR and simulators helps workers gain skills for today’s construction jobs.

Strategies to Attract and Retain Skilled Workers

Getting and keeping skilled workers takes effort. Offering good pay and benefits is important. Creating a safe and positive workplace also helps. Safety training makes workers happier and less likely to quit. About 60% of worker training money goes to safety programs.

Supporting trade schools and special training programs is also smart. In 2023, over $800 million was spent on these programs. This shows how important they are. By focusing on worker growth and safety, you can keep talented workers and stay ahead in the industry.

Evidence Description | Quantitative Data |

|---|---|

Retention of high performers with skills-based approach | 98% more likely |

Investment in safety education and training | 60% of workforce training funds go here. |

Investment in trade and specialty programs | Over $800 million spent in 2023. |

Diversity and Inclusion in the Construction Workforce

Diversity and inclusion are now very important in construction. Companies are working to create fair and welcoming workplaces. This change improves teamwork and helps solve problems better. Including people from all backgrounds makes teams stronger and more creative.

The construction industry is improving in diversity. Women now make up 9.9% of workers. Black workers are 6.2%, and Asian workers are 2%. These numbers show progress, but more work is needed to include everyone.

Group | Percentage |

|---|---|

Women | 9.9% |

Black Workers | 6.2% |

Asian Workers | 2% |

To support inclusion, try some helpful strategies. Offer mentorship programs for underrepresented groups. These programs build confidence and teach new skills. Also, give diversity training to all workers. This helps everyone understand and respect each other.

Make your workplace safe and friendly for all. Listen to concerns and fix problems quickly. Celebrate different cultures to bring teams closer together. By doing these things, you follow new trends and help create fairness in construction.

Diversity and inclusion are good for business too. Different ideas and views help companies stay ahead. A diverse team can adapt better to changes and challenges.

Safety Innovations in Construction Trends

Wearable Technologies for Worker Safety

Wearable devices are changing safety on construction sites. These gadgets check health and surroundings to spot risks early. For example, they can warn workers about heat stress before it gets worse. By using real-time data, wearables help keep workers safe from dangers.

These devices do more than improve safety. They also boost work efficiency by lowering injuries and accidents. Workers can focus better without worrying about getting hurt. For instance:

Wearables reduce injuries by tracking conditions on-site.

They make job sites safer and more productive.

Using wearable technology follows new trends and keeps projects safe and efficient.

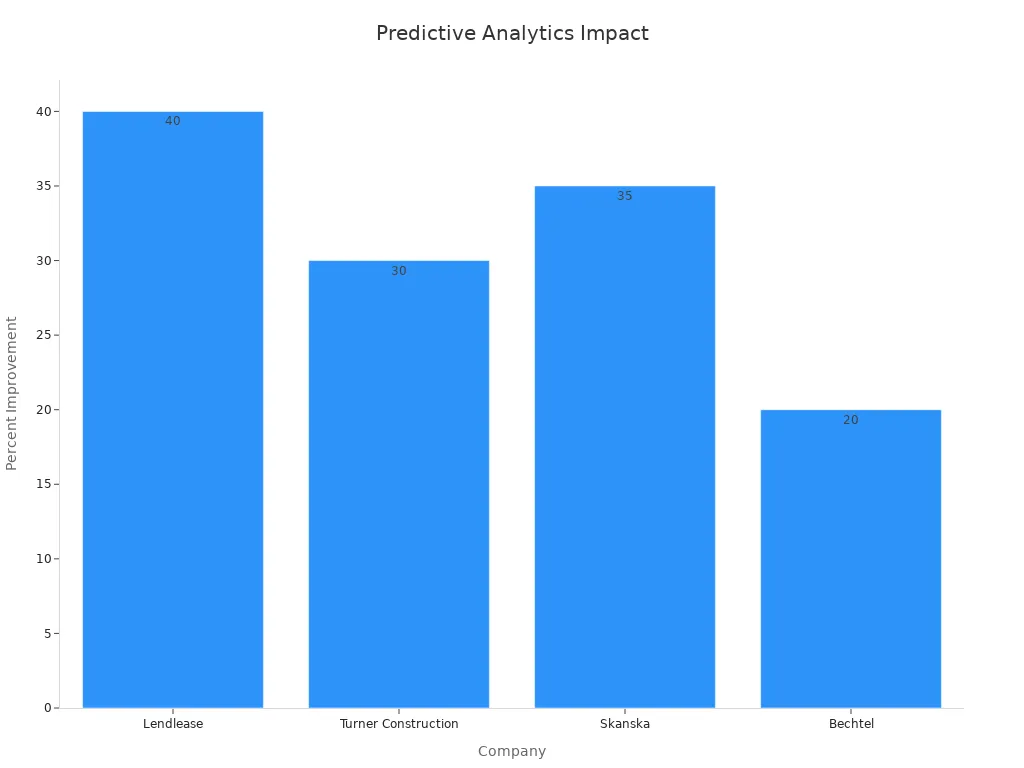

Predictive Analytics for Risk Management

Predictive analytics is changing how risks are handled in construction. It studies data to predict and stop accidents before they happen. Companies using this tech have seen big safety improvements.

Company | Focus Area | Results |

|---|---|---|

Lendlease | Equipment-related injuries | 40% fewer equipment injuries. Better schedules to avoid worker fatigue. |

Turner Construction | Fall-related incidents | 30% fewer fall injuries. Workers follow safety gear rules more often. |

Skanska | Electrical safety issues | 35% fewer electrical problems. Faster and smoother electrical work. |

Bechtel | Heat stress | 20% higher worker output. Fewer heat-related illnesses. |

This technology not only cuts down on injuries but also improves work speed. Using predictive analytics helps create safer and more effective job sites.

Enhancing Safety Culture Through Technology

Technology is key to building a strong safety culture. Tools like mobile apps, drones, and augmented reality (AR) are making this possible. These tools help workers spot dangers and avoid accidents. For example:

Mobile apps can lower workplace accidents by 57%.

Drones improve safety standards on sites by 55%.

AR increases hazard awareness to 90%, compared to 48% without it.

Adding these tools to your projects builds a safety-first mindset. This protects workers and matches the trends shaping construction in 2025.

Drones for Site Monitoring and Hazard Detection

Drones are changing how construction sites are checked for dangers. These tools make it safer and easier to manage projects. They are especially helpful in risky areas. Using drones can protect workers and lower accidents.

Drones with good cameras take clear pictures of the site. These pictures help find dangers during safety checks. Drones can fly over big areas fast, saving time and effort. They also record problems and send alerts to fix issues quickly. Real-time warnings let teams act fast to stay safe.

Drones help follow safety rules better. They use past data to guess future risks. Alerts keep workers and tools away from danger zones. These features show how technology improves safety and work speed.

FAQ

What are the newest construction trends for 2025-2030?

New trends include eco-friendly building, smart robots, and digital tools. These changes make work faster, safer, and less wasteful.

How does technology make construction safer?

Tools like wearables, drones, and smart systems find risks early. They stop accidents, check worker health, and follow safety rules.

Why is being eco-friendly important in construction?

Eco-friendly methods protect nature and save resources. Green designs, zero-energy buildings, and recycling cut pollution and help the planet.

How can companies fix worker shortages in construction?

Companies can pay better and give good benefits to workers. Training, virtual reality, and fair workplaces keep skilled workers happy.

Why does diversity matter in construction?

Diversity brings new ideas and teamwork. Fair workplaces attract different people, helping solve problems and improve projects.