When it comes to construction, accuracy is everything. A few inches off here or there might not sound like much, but on a job site, it can mean wasted materials, extra hours, and busted budgets. That’s where excavator GPS systems come in.

What is an Excavator GPS System?

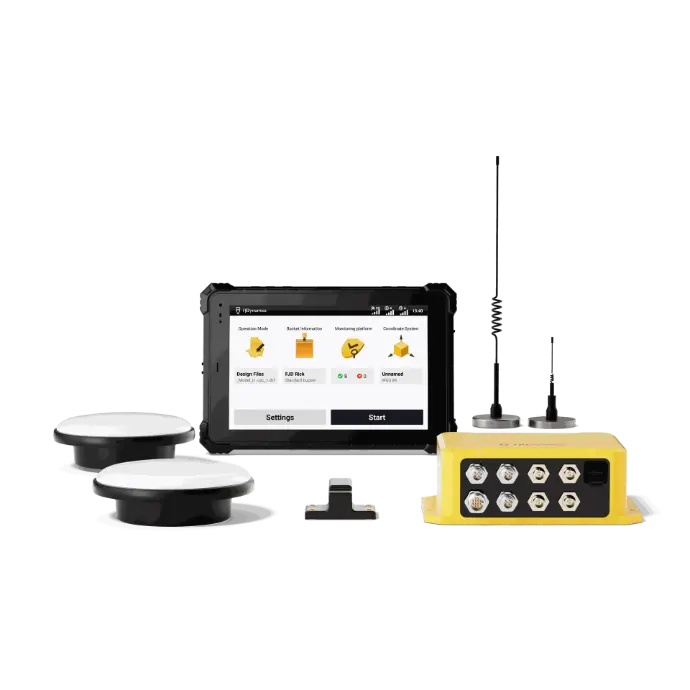

Excavator GPS systems bring tech to the construction site in a big way. Imagine being able to see exactly where to dig, how deep, and at what angle—all with the help of GPS. That’s what these systems do. Instead of eyeballing your work, you have a digital guide, so every move is precise. It’s like turning your excavator into a high-tech, precision machine.With the FJD G31 PRO, you’re getting excavator 3D guidance system, which means you can see the whole picture: the ground contours, the depth, and the layout. For construction pros, this level of detail takes the guesswork out and puts control back in your hands.

Why Use GPS on Excavators?

For those new to the idea, using GPS on an excavator might seem a little over the top. But here’s why it’s such a game-changer in construction:- Laser-Sharp Accuracy: Excavator GPS systems provide accuracy that just can’t be achieved manually. With 3D guidance, you know exactly where every scoop of earth should go. It’s perfect for grading, trenching, and even complex cut-and-fill work. With the FJD G31 PRO, you’re looking at a setup designed to help you get it right the first time.

- Faster Completion, Lower Costs: No one likes redoing work, especially when time is money. Excavator GPS systems help you do the job right in fewer passes, which means more projects completed and more money saved. The FJD G31 PRO keeps things efficient, helping you finish jobs faster and with less fuel.

- Increased Safety: With the guidance of GPS, there’s less need for people to be around your excavator for measurements or direction. That means fewer folks near heavy machinery, which ultimately makes the whole job site safer.

Excavator Guidance Systems: The Tech Behind the Precision

So, what’s the deal with excavator guidance systems? Well, 3D guidance systems like the FJD G31 PRO takes traditional GPS tech to another level by giving you real-time depth and angle information. Instead of just showing you where the excavator is, 3D systems show you the terrain and contours in full detail.With excavator GPS, you’re seeing the exact shape of the ground you’re working on. This kind of detail allows for exacting work that would be difficult without it, making every cut and grade as smooth as possible.Key Features to Look for in an Excavator GPS System

If you’re shopping around for GPS systems for your excavator, here are a few features you’ll want to keep in mind:Real-Time Positioning and Monitoring

A quality GPS system provides real-time feedback on the excavator’s exact location, depth, and angle. This instant feedback helps operators adjust quickly, reducing mistakes and rework. Look for a system with a clear, easy-to-read display that shows your current and target locations.3D Mapping and Guidance

3D GPS systems give operators a full picture of the terrain, making complex grading and contouring much easier. The 3D view shows detailed contours, slopes, and elevations, helping ensure precise cuts and fills. For high-accuracy jobs, 3D systems are essential, particularly in environments with uneven terrain.

Easy-to-Use Display Interface

The display should be intuitive and easy to use, even in a bumpy environment. A well-designed interface ensures operators can focus on the job instead of getting distracted by complicated controls. Look for customizable screen views, touch controls, and an interface that shows critical info at a glance.Data Logging and Project Tracking

Data logging is a great feature for operators and managers alike. It records each step of the job, allowing you to analyze performance, track progress, and save completed job files for reference or regulatory reporting. This can be especially valuable for large projects or when you need to share data with other contractors.Benefits of Using GPS for Construction Projects

For those working in construction, excavator GPS systems provide an edge that keeps your work high-quality and efficient. Here’s a quick look at the big benefits:- Saves Money on Fuel and Resources. You’re doing less rework and fewer passes, which means less fuel burned and less wear on your machine.

- Enhances Project Management. When you know exactly where every inch of earth needs to go, you can better coordinate your crew and manage time.

- Eco-Friendly Operations. Precise work cuts down on wasted fuel and unnecessary moves, making GPS-guided construction a greener option.

How Do GPS Excavators Work?

Excavator GPS uses satellite signals to provide precise location data for each movement the machine makes. Here’s a simplified look at how it all comes together:- GPS Satellites and Receivers: Satellites send signals down to the GPS receiver mounted on the excavator. These signals provide location data that the receiver interprets to show the excavator’s position on a 3D map.

- On-Screen Guidance and Mapping: This data is processed and displayed on a monitor in the cab, where operators can see real-time information about depth, angle, and location. The screen shows the exact spot on the site where digging or grading needs to happen, making it easy to follow a precise plan.

- Automated Control Options: Many modern systems have automated or semi-automated control features. This means the system can automatically adjust the excavator’s arm and bucket angles to meet specific target depths or grades, taking a lot of the guesswork out of the process.

- Sensors for 3D Accuracy: Advanced GPS systems for excavators also have additional sensors, often mounted on the excavator’s arms and bucket, to calculate precise angles and measurements in three dimensions. This allows operators to stay on target as they dig, even on complex sites.

How Accurate is the GPS on an Excavator?

GPS accuracy on an excavator can be impressive, depending on the system used. Standard excavator GPS systems can typically reach accuracy within a few inches (often around 1-2 inches) when set up with Real-Time Kinematic (RTK) corrections. RTK uses signals from a base station nearby to eliminate most of the interference that causes small positioning errors.Without RTK corrections, standard GPS systems are accurate within a foot or so, which might be suitable for rough grading but isn’t as precise as most construction tasks demand. For highly detailed work, especially in tight construction spaces, the combination of RTK and additional sensor data can make excavator GPS systems extremely accurate, letting operators follow project plans down to the inch.